Table Of Content

In this comprehensive guide, we will dissect the different facets of IoT crucial for OEMs and how the technology can enhance product performance, enable remote monitoring, and facilitate predictive maintenance.

Moreover, we will take you through the vital elements involved in implementing IoT solutions, such as approaches to data collection, requirements for firmware/software development, system integration, and strategies for successful cloud connectivity.

Whether you are taking your first steps into the IoT realm or are keen to expand your knowledge, this guide aims to deliver insightful nuggets of information and pragmatic advice to help you steer successfully through the IoT sphere.

Important usages of IoT for industry OEMs

This section is dedicated to shedding light on some pivotal deployments of IoT, carefully chosen for their specific relevance and transformative potential within the OEM landscape:

1. Automation

- IoT devices with sensors are deployed on equipment or machinery to collect real-time data on parameters such as temperature, vibration, or operating conditions. The system analyzes this data to anticipate maintenance needs and optimize schedules.

- GE implemented IoT in their wind turbines, allowing real-time performance monitoring and predictive maintenance. This led to a 20% decrease in downtime and a 15% increase in annual energy production.

2. Asset tracking and inventory monitoring

- IoT devices such as RFID tags, sensors, actuators, and cameras are deployed on assets to collect and transmit real-time data on asset conditions, location, and movement. This continuous monitoring allows for tracking asset performance, inventory levels, and asset location.

- Implementing IoT-based GPS tracking solutions in the logistics industry, for instance, can lead to up to 30% reductions in fuel costs and a 25% increase in delivery efficiency.

3. Equipment management

- IoT is used to track equipment performance, utilization, and maintenance requirements using sensors and actuators deployed on equipment to collect data on various parameters. Systematic equipment management ensures optimal performance and extends the equipment's lifespan.

- For example, Caterpillar, a leading manufacturer of construction equipment, utilizes IoT sensors in their machinery to monitor performance and maintenance needs. This data-driven approach has resulted in a 15% reduction in maintenance costs and a 20% increase in equipment uptime.

4. Anomaly detection

- By analyzing the data collected from IoT devices, anomalies and deviations from normal behavior can be identified. ML algorithms can be employed to analyze patterns, detect anomalies, and generate alerts or notifications.

- For instance, if a sudden increase in temperature or unusual vibration patterns are detected, it can indicate a potential issue or failure. The floor personnel can then quickly take remedial action to fix the problem.

5. Formula management

- IoT sensors are integrated into the formulation processes, monitoring parameters such as ingredient measurements, temperature, or process parameters.

With real-time data monitoring and control, you can ensure accurate formulation, track ingredient usage, and maintain consistent product quality. This IoT use case is especially prominent in the pharmaceutical and food processing sectors.

6. Security

- IoT devices, such as surveillance cameras, access control systems, or motion sensors, can detect and alert in real-time and remotely. The system can identify and classify suspicious activities, unauthorized access attempts, or abnormal behavior.

The timely alerts enable immediate responses, such as notifying security personnel, triggering alarms, or initiating automated security measures. According to a study by Gartner, organizations that implement IoT-enabled security systems can experience up to 70% faster response times to security incidents and a 30% reduction in security breaches.

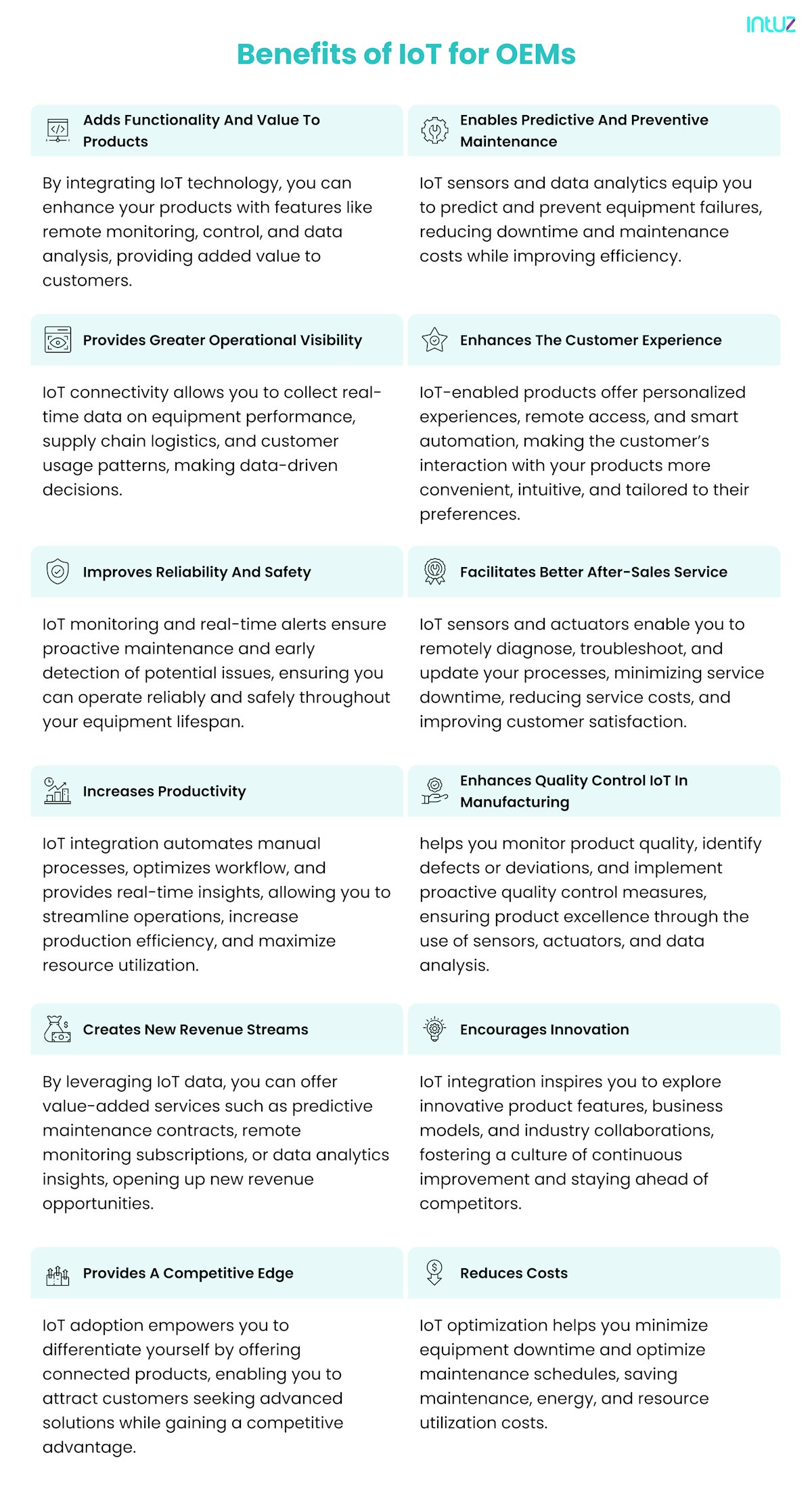

Benefits of IoT for OEMs

Implementing IoT technology offers numerous benefits for OEMs across different industries. Here are some of the key advantages:

IoT hardware requirements for OEMs

IoT hardware encompasses the physical components and devices enabling IoT ecosystem connectivity, which include IoT sensors, computer chips, actuators, and cables. Leveraging these facilitates seamless data flow throughout the technology stack and at all levels. Therefore, selecting the right IoT hardware is critical for ensuring the smart devices’ optimal performance and functionality. Here are the key hardware requirements:

I. Choosing the right sensors for IoT solutions

Sensors measure physical variables such as temperature, humidity, pressure, smoke, gas, light, sound, vibration, airflow, water flow, speed, acceleration, proximity, GPS position, and altitude and convert them to electrical signals (voltages).

These components vary in their functionality and may be used in a wide assortment of conditions. For example, proprioceptive sensors monitor the internal state of the device.

Sensors such as push buttons, sliding controls, or touch screens may be used to interact directly with a device (Human-Machine Interface). The following are the top elements to keep in mind while selecting sensors for your IoT hardware:

1. Level of accuracy

To determine the required accuracy, consider the specific data you are collecting and its impact on your IoT platform. For example, if you monitor temperature for HVAC control, a few degrees of variance may be acceptable, while precise measurements are key in medical applications.

Hence, check the sensor datasheets for accuracy specifications and ensure they meet your requirements. Depending on your needs, look for sensors with a low percentage error. They must also have built-in calibration or compensation features to maintain accuracy.

2. Financial viability

When evaluating costs, consider both the upfront and long-term costs of sensor deployment, calibration, and ongoing maintenance.

Compare the prices of different sensor models and manufacturers while considering their:

- Accuracy

- Reliability

- Compatibility with your IoT platform

Cheaper sensors may require more frequent calibration or have shorter lifespans, impacting the overall financial viability.

3. Calibration frequency

Calibration requirements vary depending on the sensor type and IoT solution. Some sensors may require periodic calibration (e.g., every few months), while others may be more stable and require calibration less frequently (e.g., annually).

Consult the sensor manufacturer’s recommendations for calibration intervals. They often provide guidelines based on the sensor’s stability and application requirements.

4. Environmental side-effects

Identify the specific environmental factors that can impact your IoT sensor's performance. For example, temperature fluctuations may affect pressure or gas sensors, while moisture or humidity may impact electronic components.

Look for sensors with appropriate environmental ratings, such as IP (Ingress Protection) ratings for dust and water resistance or NEMA (National Electrical Manufacturers Association) ratings for industrial applications.

5. Sensor size based on application

Evaluate the physical constraints of the installation location, including:

- Mounting options

- Space availability

- Integration requirements with other components or devices.

Choose sensors with compact form factors, modular designs, or flexible mounting options to fit within limited spaces.

You can go for wireless or miniaturized sensor options, such as surface-mount devices or microelectromechanical systems (MEMS) sensors, which are apt for small-scale apps.

6. Power source based on application

Factors such as portability, availability of continuous power, and energy harvesting techniques influence the choice of power source.

Battery-powered sensors, for instance, are suitable for portable devices, while wired sensors are ideal for fixed installations. On the other hand, energy harvesting sensors use ambient energy sources to eliminate the need for batteries or wired power connections.

II. Primary gateway hardware requirements for IoT solutions

An IoT gateway is a central hub connecting IoT devices and sensors to cloud-based computing and data processing, simplifying communications and management. It aggregates data from multiple sources, providing a single point of contact for cloud infrastructure.

IoT gateways also act as a protective layer between IoT devices and the internet. No wonder much thought must be given while determining the primary gateway hardware requirements:

1. Chipset

Evaluate the processing power of the chipset based on the specific requirements of the IoT gateway application. Consider factors such as:

- Number of devices to be connected

- Data processing complexity

- Real-time processing needs

Look for a chipset with higher clock speeds and multiple cores to handle data efficiently. Assess its computational capabilities, including support for advanced algorithms, ML, or image processing.

You could choose hardware with specialized co-processors or accelerators to offload specific computational tasks and enhance overall performance.

In addition, check if the chipset:

- Supports other relevant communication standards required by the specific IoT devices or cloud platforms

- Is compatible with Zigbee, Z-Wave, or LoRaWAN

- Is scalable for future enhancements or upgrades

Check if it can accommodate additional functionalities or increased data processing requirements as the IoT ecosystem evolves.

2. Memory considerations

Ascertain the complexity of your IoT application and the data it generates. Consider the number of connected devices, data processing requirements, and future expansion plans to determine the appropriate memory capacity for smooth operation.

For instance:

- The current RAM should be sufficient for real-time data processing.

- The option of flash storage must be available for local data storage and retrieval.

- You must know the total amount of data stored and processed on the gateway.

Ensure the selected option has enough memory for Over-The-Air (OTA) firmware updates without impacting regular operations.

3. Connectivity modules

IoT gateways require various connectivity modules to establish communication between sensors, devices, and cloud platforms. Choose a connectivity module that provides the necessary range, whether short-range (Bluetooth, Zigbee) or long-range (GSM, LoRaWAN).

Consider the power consumption limitations of the IoT gateway application. A module with low power consumption works if energy efficiency is a priority.

Assess the compatibility of the connectivity module with other devices and systems in the IoT ecosystem, and check if it adheres to industry-standard communication protocols and seamlessly integrates with the IoT app’s existing devices or cloud platforms.

4. Environment and power source

Check out the power source options suitable for a specific environment. For example, consider solar power or battery-operated solutions in remote or outdoor settings, while indoor installations with readily available power sources may be compatible with mains power.

Take into account factors such as:

- Exposure to harsh weather conditions

- Temperature range

- Moisture

- Humidity

- Dust

Assess the physical durability requirements of the IoT gateway, particularly if it may encounter vibrations, shocks, or rough handling.

You must also explore different power source options that align with the specific environment, such as mains power, battery-operated solutions, or renewable energy sources like solar power.

5. Form factor and clock/auto time zone features

Estimate the available space for installing the IoT gateway and the specific mounting options required in the application, such as:

- Rack-mounted

- Wall-mountable

- DIN rail-mountable

Choose a form factor that enables easy integration and deployment in space constraints.

Accurate timekeeping is crucial for synchronization, data analysis, and data integrity. Gateways should have reliable clock mechanisms, including the ability to auto-adjust to different time zones. Choose hardware with built-in real-time clocks (RTC) or support for external time synchronization protocols like NTP.

6. Hardware cost and performance

Compare different gateway options and evaluate their prices concerning their features, capabilities, and compatibility with the IoT application.

For instance:

- The long-term benefits and ROI provided by the chosen hardware solution.

- The potential impact on operational efficiency, data processing speed, scalability, and overall system performance.

It is essential to balance the hardware cost and the expected performance, ensuring that the selected solution meets the necessary requirements without incurring unnecessary expenses.

Additionally, determine the availability of technical support and the reputation of the hardware manufacturer or vendor. Go with someone who can offer timely assistance.

Pre-selection considerations for IoT hardware: Telemetry data on the cloud or local network?

1. If you require your telemetry data to be on the cloud:

Cloud connectivity offers several advantages regarding data accessibility, remote monitoring, and analysis. Explore hardware options that support seamless integration with cloud platforms. For instance:

- WiFi allows your device to connect to local wireless networks and access the internet for cloud connectivity.

- WAN (Wide Area Network) refers to cellular connectivity, enabling your device to communicate over cellular networks and access the cloud.

- LoRaWAN is a long-range, low-power wireless protocol designed for IoT devices to connect to the cloud through a LoRaWAN gateway.

2. If you require your device data to be limited to the local network only:

Local network-only data transmission might be preferred in specific scenarios due to security concerns, latency requirements, or limited infrastructure. For localized data communication, consider hardware options that support low-range and local area network protocols, such as:

- Bluetooth is a short-range wireless protocol commonly used for device-to-device communication within a limited range.

- LAN (Local Area Network) refers to wired Ethernet connectivity, allowing devices to communicate within a local network.

- Modbus is a serial communication protocol used in industrial environments for local device-to-device communication.

- Zigbee is a low-power, low-range wireless protocol for home automation and IoT applications within a local network.

Consider your specific requirements and the capabilities of the IoT hardware options available to choose the most suitable one for your needs.

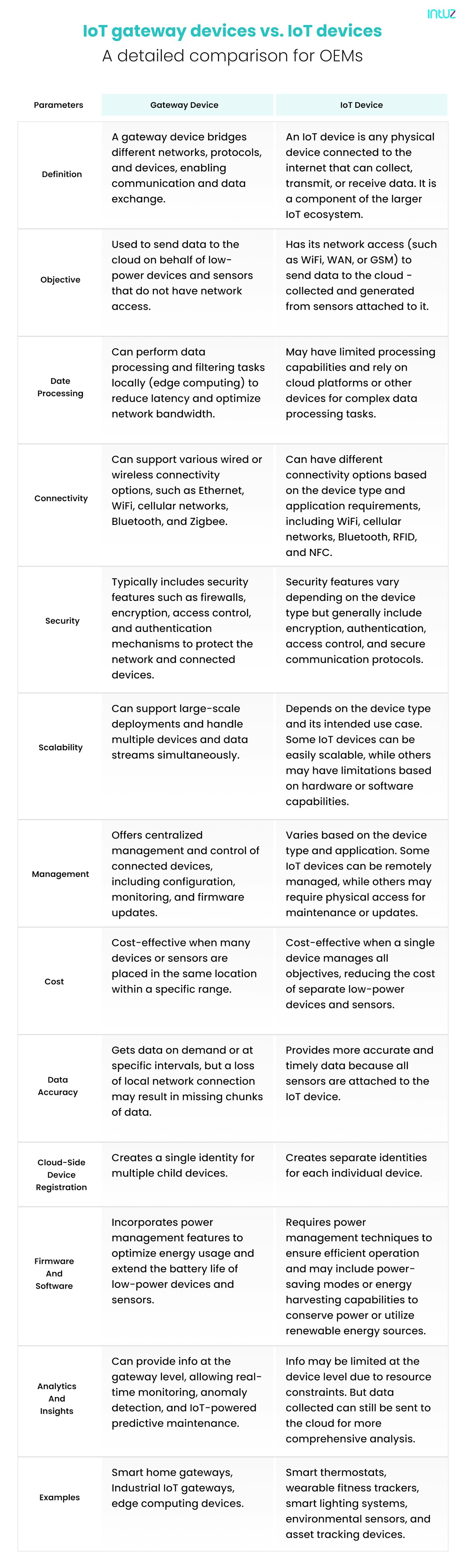

IoT gateway devices vs. IoT devices: A detailed comparison for OEMs

When designing and implementing IoT solutions, aim to select the appropriate hardware components that will form the foundation of your IoT ecosystem. Two crucial elements in this decision-making process are the IoT gateway device and the IoT device itself.

Understanding the distinctions between these two is essential to making informed choices that align with your specific application requirements. Here is how they compare:

IoT network considerations for OEMs

IoT products rely heavily on networks to establish communication channels with gateways, sensors, servers, routers, and other IoT devices. This communication involves transmitting and receiving data, enabling them to carry out their intended functions.

Although there are a wide range of choices regarding network connectivity options, not all are created equal. Some are not specifically designed for IoT and have limited use cases. On the other hand, some are purpose-built to cater to specific types of IoT applications.

The following section explores the factors that should be considered when evaluating IoT network connectivity for your IoT ecosystem, along with an overview of the most popular options available:

1. WiFi

WiFi uses radio waves to transmit data between devices and a wireless router or access point:

- It is suitable for IoT applications that involve the transfer of large amounts of data. This includes applications like video streaming, real-time monitoring, and high-resolution sensor data collection, where a fast and reliable wireless connection is necessary.

- WiFi can leverage existing internet infrastructure, such as routers and access points, making it easier to integrate IoT devices into an already established WiFi network.

The only con is that WiFi can consume more power compared to other connectivity options, which may not be suitable for battery-powered devices. The range can be limited, especially in environments with obstacles or interference. Setting up and managing WiFi networks may also require technical expertise.

2. Bluetooth

Bluetooth is well-suited for short-range communication within limited physical proximity. It allows IoT devices to connect and exchange data wirelessly over distances typically up to 100 meters, depending on the Bluetooth version and power levels.

- It has broad device compatibility, with most modern smartphones, tablets, laptops, and IoT devices equipped with Bluetooth capabilities. This compatibility makes it easier to connect and communicate between different devices in an IoT ecosystem.

- It supports encryption, authentication, and authorization mechanisms to protect data privacy and prevent unauthorized access.

- Protocols, such as the Generic Attribute Profile (GATT) for BLE and the Universal Asynchronous Receiver-Transmitter (UART), provide standardized frameworks for building IoT applications on top of Bluetooth. For instance:

- GATT is well-suited for IoT applications that involve exchanging sensor data between devices. IoT devices equipped with sensors, such as temperature, humidity, or motion sensors, can use GATT to transmit this data to a central device or server for processing and analysis.

- UART is often used when real-time data transfer is crucial. IoT applications that require real-time monitoring or control, such as robotics or automation systems, can benefit from the reliable and immediate data transfer offered by UART.

However, Bluetooth has a limited range compared to other wireless technologies, typically around 10 meters. It may not be suitable for devices that require long-range communication. The data transfer rate is also lower compared to WiFi, which can be disrupted by physical obstacles.

3. Zigbee

Zigbee is used in solutions where a large number of low-power IoT devices need to communicate with a central hub or gateway, such as home automation, smart lighting, and industrial monitoring systems.

- It can be used to build energy management systems that monitor and control energy consumption in buildings. It enables the integration of smart meters, thermostats, and other energy-related devices, enabling efficient energy usage and demand response.

- By using Zigbee tags or beacons, objects or assets can be easily tracked within a specific area, such as a warehouse or logistics facility, because of its mesh topology.

The only disadvantage is that Zigbee has a shorter range than WiFi or cellular networks, typically around 10–100 meters, and it may require a Zigbee coordinator or gateway for connecting to the internet.

4. LoRaWAN

Long-Range Wide Area Network, or LoRaWAN, is used in applications such as smart agriculture, asset tracking, and smart city apps.

- It offers excellent range capabilities, allowing devices to communicate over several kilometers in outdoor environments. If your IoT deployment requires long-range connectivity, especially in rural or remote areas, LoRaWAN can be a suitable choice.

- It is designed to operate on low power, making it ideal for battery-powered or energy-constrained IoT devices.

- Deploying a LoRaWAN network infrastructure is generally more cost-effective compared to cellular networks or other LPWAN technologies as it requires fewer gateways and operates in unlicensed frequency bands.

However, LoRaWAN has lower data transfer rates than WiFi or cellular networks, typically a few kilobits per second. It requires the deployment of LoRaWAN gateways to create network coverage, which may involve higher upfront costs.

5. Cellular networks

Cellular networks (e.g., 2G, 3G, 4G, or 5G) are commonly used in asset tracking, fleet management, and remote monitoring applications.

- They are designed to handle large-scale deployments, making them suitable for IoT applications that involve a high number of devices.

- They offer a robust infrastructure capable of supporting thousands or even millions of connected devices simultaneously.

- Cellular networks often incorporate strong security measures, including encryption protocols, to protect data transmitted between IoT devices and backend systems. This is essential for IoT apps, where data privacy and integrity are critical concerns.

However, this option consumes more power than other low-power wireless technologies, which may not be suitable for battery-powered IoT devices with long operational lifetimes.

Subscription costs for cellular connectivity can add to the overall expenses. In remote or rural areas, network coverage may be limited.

Protocols for connecting the device to the cloud:

6. MQTT

Message Queuing Telemetry Transport, or MQTT, is lightweight and efficient, making it suitable for resource-constrained devices and low-bandwidth networks.

- This model is well-suited for scenarios where multiple devices need to exchange information without direct point-to-point communication. It allows for decoupling and scalability in IoT systems.

- Many IoT devices operate on limited power sources, such as batteries. MQTT's lightweight nature and efficient data transfer help conserve power, making it a good choice for energy-constrained devices.

The only con is that MQTT relies on a centralized broker, which introduces a single point of failure. The broker must be highly available and scalable to handle many connected devices.

Plus, the protocol does not provide built-in security mechanisms and requires additional measures such as Transport Layer Security (TLS) for secure communication.

7. AMQP

Advanced Message Queuing Protocol, or AMQP, is used in scenarios where message durability, transactional support, and complex routing scenarios are necessary.

- AMQP supports multiple messaging patterns, including point-to-point, publish-subscribe, request-reply, and more. This versatility allows you to choose the appropriate pattern based on the communication requirements of your IoT application.

- It supports a wide range of programming languages, platforms, and messaging brokers, making it easier to integrate with existing IoT systems and devices.

The only thing is AMQP may introduce additional complexity compared to lightweight protocols like MQTT. It requires more computational resources and bandwidth compared to MQTT. Implementing AMQP infrastructure may also involve higher upfront costs.

8. HTTP

Hypertext Transfer Protocol, or HTTP, is suitable for IoT applications that require direct communication between devices and cloud services using standard web protocols.

- It follows a request-response model, where a client sends a request to a server, and the server responds with the requested data. This model is suitable where IoT devices need to interact with web services or retrieve information from remote servers.

- HTTP includes built-in support for caching and proxy servers. Caching can be beneficial in IoT scenarios where data is frequently accessed or where devices have limited bandwidth. Proxy servers can help offload processing, caching, and load balancing.

Disadvantages? HTTP is not the most efficient choice for resource-constrained IoT devices due to its overhead and verbosity. For devices with limited processing power or bandwidth constraints, lightweight protocols like MQTT or CoAP may be more suitable

Key considerations for comparing IoT network connectivity solutions

- Coverage: Different connectivity technologies have varying coverage areas, ranging from local networks with limited range to wide-area networks that provide broader coverage. Assessing coverage ensures that your IoT products can establish a reliable connection in the intended deployment locations.

- Bandwidth: Consider your devices’ data-intensive tasks and ensure that the chosen connectivity solution can accommodate the required bandwidth. For instance, cellular networks are apt for apps that involve large data transfers, and LPWAN is more suitable for transmitting smaller amounts of data intermittently.

- Power consumption: As IoT devices rely on limited battery power, determine the amount of power they will consume while transmitting or receiving data over the chosen connectivity solution. Low-power connectivity options like LPWANs or BLE can operate for extended periods without frequent battery replacements.

- Cost: There are cost implications for the chosen connectivity solution. Check if you must establish and maintain your infrastructure, such as base stations or gateways. Additionally, list the necessary components and estimate any subscription fees or data usage charges associated with the connectivity solution.

- Security: Ascertain whether the chosen network type enhances or diminishes the protection against unauthorized access and misuse of your IoT devices and data. Look for connectivity solutions that offer robust security measures, such as encryption, authentication, and secure protocols, to avoid potential threats.

- Mobility: Check if the chosen connectivity can effectively maintain the connection and provide seamless communication while the devices move. This is crucial for applications such as asset tracking, vehicle telematics, or wearables that want connectivity on the go.

Firmware development for Industrial IoT solutions

Firmware development typically involves designing and coding the software that runs on the IoT device, enabling its functionality, and defining its behavior. This section analyzes critical aspects that guide firmware development and ensures the IoT device operates as intended:

1. Determine the operations you want for the device

This includes understanding your device’s purpose, intended use cases, and the specific features it should support. Consider the sensors, actuators, and communication protocols required to achieve the desired functionality. Make a comprehensive list of your IoT device’s operations to serve as a foundation for firmware development.

2. Ascertain the business logic for device behavior

You must establish the business rules and logic that govern the behavior of your IoT device under various conditions. This involves the following tasks:

- Understand the intended purpose and functionality of the IoT device as specified by the product requirements and documentation.

- Find out the desired behavior and functionality from a user’s perspective. This may involve studying user stories, feedback, and interviews to gain insights into user expectations.

- Consider the various environmental conditions and external factors that may impact the device's behavior. For example, temperature, humidity, location, and network connectivity.

- Identify the events or inputs that should trigger specific actions or behaviors in the device, which can include user interactions, sensor readings, time-based triggers, or external signals.

- Establish the appropriate responses or actions that the device should take when triggered by specific events, including performing certain calculations, activating or deactivating features, sending notifications, or interacting with other devices or systems.

- Define how the device should behave when encountering errors, exceptions, or unexpected situations - for example, providing informative error messages, logging errors for diagnostics, or implementing fallback strategies.

Once the business logic is defined, validate and test the device’s behavior under various scenarios and conditions. This helps ensure the implemented logic aligns with the desired functionality and meets the intended requirements.

3. Factor in the size of the firmware

Firmware size is critical in IoT device implementation as it affects the choice of memory and the feasibility of performing OTA updates. To determine the same, consider:

a. Code size: Calculate the approximate size of the firmware code by considering the programming language, libraries, and frameworks you will be using. This estimation will help you understand the memory requirements.

b. Data storage: Assess the amount of non-volatile memory required to store device-specific data, such as configuration settings, calibration values, and persistent storage needs. This data should be factored into the overall firmware size calculations.

c. OTA considerations: If you plan to provide OTA updates to your devices, ensure that the firmware size is suitable for OTA transmission. Remember that OTA updates require additional storage space for storing the current and new firmware versions during the update process.

e. Optimization techniques: Employ optimization techniques such as code compression, reducing unnecessary dependencies, or utilizing data compression algorithms to minimize firmware size without compromising functionality.

4. Choose the programming language based on the chipset

Different chipsets have varying architectures and instruction sets, often dictating the compatible programming languages for firmware development in Industrial IoT devices or IoT gateway devices.

Some common chipsets used in IoT devices include the following and may their preferred programming languages:

- STMicroelectronics STM32 Series chipsets are commonly programmed using languages such as C and C++. The STM32Cube development platform offers support for these languages and provides a comprehensive ecosystem for developing applications on STM32-based devices.

- Qualcomm Snapdragon chipsets often utilize programming languages such as C and C++. These languages are well-supported by the Android development framework, which is commonly used for Snapdragon-based IoT devices.

- ARM Cortex-M Series chipsets are typically programmed using languages such as C and C++. These languages are widely supported by development tools, compilers, and libraries for ARM-based microcontrollers.

- ESP8266 and ESP32 chipsets can be programmed using languages such as C and C++, and MicroPython. For IoT development specifically, the ESP8266 and ESP32 chipsets are widely favored choices. They support programming languages like C, C++, and MicroPython. When it comes to the development process, the ESP-IDF (Espressif IoT Development Framework) is widely acknowledged as the top-notch tool for programming Espressif chipsets of all kinds.

- The MediaTek LinkIt platform provides a range of development boards designed for specific use cases and capabilities. Among them are the LinkIt Smart 7688, LinkIt ONE, and LinkIt Assist 2502. These boards are equipped with processors, memory, and various connectivity options like WiFi, Bluetooth, and GPS. Additionally, they feature interfaces that allow for seamless connections between sensors and peripheral devices.

Please consider the documentation and development tools provided by the chipset manufacturer to understand their recommended programming languages and associated software frameworks.

In addition, confirm the expertise and skill set of your IoT development service provider or in-house developers. Choosing a programming language they are familiar with can expedite development and reduce the learning curve.

5. Create a document comprising all business rules for D2C (Device to Cloud) and C2D (Cloud to Device) communication

D2C communication refers to the flow of data from the IoT device to the cloud platform, which demands the following business rules to be considered:

a. Data transmission:

- Define the frequency and conditions under which IoT device data is transmitted to the cloud (e.g., periodic intervals, threshold-based triggers, event-driven).

- Specify the data format, including the payload structure and encoding mechanisms.

b. Error handling:

- Deploy robust error-handling mechanisms to handle exceptional conditions and recover gracefully.

- Log and store relevant error information for debugging and troubleshooting purposes.

- Include meaningful error messages and notifications to aid in diagnosing issues.

c. Data processing:

- Specify how the cloud platform processes incoming IoT device data (e.g., data validation, transformation, aggregation, filtering).

- Define rules for handling data anomalies, outliers, or abnormal patterns detected at the device level.

- Establish data storage and retention policies, including data archival, real-time analytics, and long-term data management.

On the other hand, C2D communication sends commands or instructions from the cloud platform to IoT devices. Consider the following business rules.

a. Command delivery:

- Determine the mechanism for delivering commands to devices (e.g., push notifications, message queues, or direct device polling).

- Define the prioritization and sequencing of commands when multiple devices are involved.

b. Command processing:

Specify how devices should interpret and execute received commands.

- Define validation and authentication mechanisms to ensure that only authorized commands are executed.

- Handle command conflicts or dependencies that may arise due to simultaneous or conflicting instructions.

c. Firmware/software updates:

- Establish rules for firmware or software updates initiated from the cloud on devices.

- Sort the frequency, scheduling, and versioning mechanisms for delivering updates.

Note: We have provided only a general framework for defining business rules. Adapt and tailor these rules according to your IoT system’s specific requirements and constraints.

6. Optimize memory usage for faster IoT device operations

Efficient code, lightweight libraries, data compression, and smart data storage policies will improve IoT device performance, responsiveness, and user satisfaction.

But memory management techniques also hold their ground and are responsible for maintaining the desired functionality. Here is how to optimize the memory usage of your IoT device.

a. Analyze memory requirements

Determine the available memory resources on the target device. Understand the limitations of RAM (Random Access Memory) and ROM (Read-Only Memory).

Identify features that the device must support and ensure they can be accommodated within the available memory.

b. Construct compact code

Leverage code compression techniques like data compression algorithms or run-time compression tools.

Use compiler optimization flags to reduce code size, avoid redundant code, and eliminate unused functions or variables.

Use efficient data serialization and deserialization techniques to reduce memory overhead during data processing.

c. Use lightweight libraries

Opt for the likes of TinyXML, NanoPB, and MicroJSON to minimize memory usage while maintaining the desired functionality.

d. Compress data for practical storage

Consider aggregating data at the device level before transmission, reducing the volume of data transferred to the cloud. Periodically purge or archive outdated or less relevant information.

e. Allocate and monitor device memory

Judiciously employ dynamic memory allocation techniques when there is a need for allocating memory at runtime based on varying data sizes, limited memory availability, or the requirement for dynamic data structures that grow or shrink dynamically.

For instance, use static memory allocation whenever possible, which involves declaring variables and data structures with specific sizes and types in the code.

7. Identify the best and most feasible device onboarding/provisioning process

This depends on factors such as the scale of your IoT deployment, the technical capabilities of the devices, the desired user experience, and the security requirements. Let us see what happens with device onboarding/provisioning:

a. Through a mobile application (Bluetooth and WiFi)

In this scenario, the device onboarding process involves utilizing a mobile application to establish a connection between the IoT device and the cloud platform. This allows end-users to interact with the device using their smartphones or tablets.

Bluetooth can be used for initial device discovery and pairing, while WiFi enables the device to connect securely to the internet and communicate with the cloud platform.

b. From direct end device (accessing cloud packages)

Here, the device can access cloud services or packages to establish its identity on the cloud platform. Ideally, the device should have built-in connectivity capabilities, such as Ethernet, WiFi, or cellular, to communicate directly with the cloud platform.

It must support secure communication protocols (e.g., HTTPS, MQTT over TLS) to establish a secure connection with the cloud and authenticate itself.

c. On the local network (using a local network broker)

In this scenario, the device is provisioned on the local network using a local network broker that registers the device in a database and facilitates communication through various protocols.

Set up a local network broker or gateway to act as an intermediary between the device and the cloud platform. It should handle device registration, communication protocol translation (e.g., HTTP to MQTT), and data forwarding to the cloud.

8. Deploy a Firmware Over-The-Air (FOTA) process

Ensure that your IoT device is designed and implemented to efficiently receive and process OTA commands from the cloud platform. This requires a well-planned firmware architecture capable of handling OTA updates seamlessly.

When an OTA command is received, your IoT device should initiate the firmware download process by retrieving the firmware image from the cloud platform. Perform integrity checks during the download to ensure the firmware’s authenticity and integrity.

In the event of an unsuccessful OTA process, provision your device to handle rollback scenarios. This involves keeping a backup of the previous firmware version, enabling the device to revert to its previous state if issues or failures occur during the current OTA process.

9. Set a process for the user to reset or restart the hardware manually

The process of manually resetting or restarting the device can vary depending on the specific device and its design. However, here are the general steps for users that you can set:

- Determine the method or mechanism the hardware device provides for resetting or restarting. This can include physical buttons, switches, or specific key combinations.

- Physically locate the reset or restart button/switch on the hardware device. Refer to the device’s user manual or documentation to find the exact location.

- If the device is currently powered on, ensure it is turned off properly before rebooting or restarting. Follow any specific shutdown procedures recommended by the device manufacturer.

- Once the device is powered off, perform the necessary actions to activate the reset or restart mechanism, which involves pressing and holding a button for a specified duration, flipping a switch, or using a specific key combination.

- Power on the device again using the appropriate power source or switch. Observe its behavior to ensure that the reset or restart was successful. The device should boot up and initialize normally, ready for operation.

Best practices for IoT firmware development

Regardless of your project requirements, target hardware, and industry standards, adhering to the following tips can help OEMs like yourself enhance the quality, security, and reliability of IoT firmware development:

Follow secure coding guidelines to protect against cyber threats. Implement input validation, data encryption, secure communication protocols, and access controls.

Use modular and structured code to enhance readability and maintainability. Break down functionality into smaller, reusable modules with well-defined interfaces.

Utilize low-power modes when appropriate and avoid unnecessary power-draining operations. Optimize device sleep/wake cycles and manage power-hungry peripherals efficiently.

Consider the hardware and platform constraints of your target IoT devices. Develop firmware that is compatible with different hardware configurations and follows industry standards to ensure interoperability.

Perform thorough testing and validation of your firmware with tools like unit testing, integration testing, and hardware-in-the-loop (HIL) testing.

Remember that firmware development is an iterative process that may involve multiple revisions and optimizations.

Enhance telemetry data collection, storage, and visualization for IIoT solutions

Telemetry collects data from remote sources using sensors and other devices and transmits it through communication systems to a central location. After that, the data undergoes analysis to facilitate monitoring of the remote system. Telemetry data is categorized into three types:

- Environmental telemetry data involves collecting information about the physical conditions and surroundings in which a system operates. For example, monitoring the temperature in a server room ensures optimal operating conditions.

- Operational telemetry data monitors a system’s performance, status, and behavior during regular operation. Examples include tracking metrics like CPU utilization, memory usage, and network traffic to improve capacity planning.

- Usage telemetry data captures information about user behavior, patterns, and preferences.For instance, analyzing user interactions such as clicks and navigation paths helps enhance interface design and identify usage trends.

Considerations for selecting a storage solution for telemetry data

In the IoT context, telemetry data aims to enable monitoring, analysis, and control of IoT devices to gain insights, make informed decisions, and automate processes in various domains. When selecting a storage solution for telemetry data, OEMs like yourself must consider:

1. Data volume

Assess the expected volume of telemetry data generated by your IoT devices. For example, the volume of usage data depends on the number of users and their interactions with IoT devices.

Choose a storage solution that scales and accommodates large data volumes to support the growing number of connected devices and their data generation capabilities.

2. Data velocity

Managing the swift production and intake of telemetry data in real-time demands a high-performance storage solution. Ideally, a distributed or edge storage system with superior throughput is essential, particularly for environmental data that requires constant monitoring and generates a substantial volume of data at high speeds.

3. Data format

You may deal with diverse telemetry data formats generated by different types of smart devices. Ensure the storage solution supports the required formats, such as JSON, CSV, or binary data, to accommodate the various data structures and efficiently store and process the telemetry data of your IoT device.

4. Data location

Consider the distributed nature of your IoT solution and ascertain where the telemetry data will be collected and stored. For geographically distributed devices and sensors, it is advantageous to employ distributed storage solutions located close to data sources.

5. Latency

Go for a storage solution that provides fast data retrieval and low response times to meet these latency requirements. For instance, real-time environmental data analysis necessitates low-latency data collection methods, particularly for time-critical applications like weather forecasting or emergency response systems.

6. Security

Prioritize a storage solution that offers robust security measures, including encryption, access controls, authentication mechanisms, and secure data transfer protocols, to protect the data from unauthorized access or breaches.

7. Compliance

If you operate in regulated industries with specific compliance requirements, such as data privacy regulations (e.g., GDPR) or industry-specific security frameworks (e.g., ISO 27001), ensure the selected storage solution complies with relevant standards and assists in meeting compliance obligations related to data storage and security.

The power of IoT data visualization

IoT data visualization makes complex datasets interpretable, understandable, and usable, facilitating the communication of insights and detecting patterns, trends, and correlations that might go unnoticed in raw, text-based data. Here are its key attributes:

1. Create and share customizable data dashboards with visualization tools.

- Utilize charts, tables, maps, and gauges to conjure up telemetry data comprehensively and meaningfully.

- Customize the appearance and layout of the dashboard to align with specific requirements and branding.

- Ensure the dashboard provides an intuitive, user-friendly interface for easy navigation and data exploration.

2. Envision data insights across systems, users, and business metrics.

- Check out the performance and health metrics of your IoT device to monitor their operational status and identify potential issues.

- Dive deep into user behavior and preferences by analyzing telemetry data related to user interactions and usage patterns.

3. Benefit from what data visualization brings to the table.

- List patterns, outliers, and correlations that may not be apparent in raw data. Visual representations highlight trends and anomalies, facilitating a deeper understanding of IoT devices’ telemetry data.

- Interactive dashboards, for instance, allow for real-time monitoring, enabling timely actions and proactive problem-solving.

- Additionally, sharing dashboards with stakeholders or exporting them to other formats facilitates collaboration, reporting, and data dissemination within your organization.

Integration with other systems

You can integrate your telemetry data systems with existing systems and data analytics tools to enhance data analysis capabilities and gain comprehensive insights. Here is how:

1. Identify and evaluate the existing systems that contain relevant data.

- Develop connectors or utilize existing connectors that can seamlessly pull data from these systems into the data visualization and analytics platform being used, such as Data Studio.

- Ensure compatibility and adherence to guidelines provided by the respective systems or tools to establish a smooth and reliable integration process.

- Explore integration options with popular data analytics tools like Google Analytics and Azure Analytics.

2. Utilize pre-existing connectors or develop custom connectors

- Establish a connection between the telemetry data systems and the analytics tools.

- Document the integration process, including the steps followed, configurations made, and any considerations specific to the integration.

- When integrating with systems that do not have pre-existing connectors, consider developing custom connectors that can pull data from various sources into the data visualization and analytics platform.

- Ensure compatibility with the target systems by following their APIs, data formats, and protocols.

Overview of telemetry data collection approaches for OEMs

The techniques can vary depending on the specific industry and the type of manufactured product. However, here are some commonly used methods:

1. Determine the ingestion mechanisms

Find out how the devices or sensors will collect the telemetry data. Common ingestion mechanisms include:

To ensure compatibility with the chosen data collection method, assess the capabilities of the devices and sensors. Factors to consider include supported protocols, data formats, and communication interfaces.

2. Evaluate network connectivity

Evaluate the network connectivity options available for transmitting telemetry data. Depending on the specific use case, consider factors such as:

Calculate the network coverage, reliability, and bandwidth requirements to choose an appropriate data collection method that ensures seamless and uninterrupted data transmission.

3. List data freshness requirements

Check whether real-time or near real-time data collection is necessary or if periodic batch updates are sufficient. Gauge the impact of data freshness on decision-making and system performance.

IoT software development requirements for OEMs

IoT software encompasses platforms, embedded systems, partner systems, and middleware, facilitating various functions such as data collection, device integration, real-time analytics, and application and process extension. In the following section, we will look at what you must keep in mind before building the software:

1. Choose the suitable programming technology

- It should be able to handle large volumes of data, efficiently process real-time data streams, and support distributed computing if necessary.

- Your programming technology needs to have built-in security features, encryption protocols, and authentication mechanisms to protect the integrity and confidentiality of your IoT data.

- For resource-constrained IoT devices, consider using languages like C, C++, or Python. For higher-level IoT applications or gateway devices, languages like Java, JavaScript, or Go can be viable options.

- Employ frameworks or libraries specifically designed for IoT development, such as Arduino or Raspberry Pi libraries, to leverage pre-built functionalities and simplify development.

2. Select an IoT cloud platform

Evaluate the platform’s ability to handle the anticipated scale of your IoT deployment, ensuring it can accommodate a growing number of connected devices and manage large volumes of data effectively.

- Examine the associated costs for device connectivity, data storage, data transfer, and any additional services you may require. Make sure the pricing model aligns with your business's needs and budget.

- Furthermore, determine how well the IoT cloud platform can integrate with your existing systems, such as ERP, CRM, or other software solutions.

- For instance, if advanced analytics, ML capabilities, or real-time data processing are necessary, ensure that the platform provides these services.

- Avoid platforms that tightly bind your devices or data to their ecosystem, as this limits your flexibility. Clearly understand the ownership rights and control over the data generated by your IoT devices.

- Ascertain its capabilities to migrate data and services to other platforms if needed. This consideration is vital if you decide to switch providers or adopt a multi-cloud strategy.

3. Define your IoT project architecture

Determine the key functionalities and services required to fulfill your end goals. For instance.

- Consider the number and types of IoT devices you will be using and how they will be connected to the IoT platform.

- What are the necessary services for device registration, provisioning, authentication, and secure communication? IoT platforms often provide services for device management, such as OTA firmware updates, remote configuration, and monitoring.

- What help do you need with real-time data ingestion, storage, and processing? For advanced analytics, you could require functionalities like data streaming, event processing, batch processing, or ML algorithms.

- To handle increased data volume and device connections, utilize cloud services like auto-scaling groups, serverless computing, or container orchestration platforms (e.g., Kubernetes, AWS Lambda).

- Implement fault tolerance mechanisms, such as redundant data storage, replication, and backup strategies, to ensure minimal downtime and data loss.

4. Determine the project feasibility for cloud computing

Design your architecture to use cloud-based services, including storage, computing power, and data analytics. Distributing the workload across numerous servers enables fault tolerance and redundancy.

In the event of a server failure, other servers seamlessly take over, reducing service disruptions. Employ technologies such as load balancers and failover mechanisms to distribute the workload and handle server failures efficiently.

Load balancers evenly distribute incoming traffic across servers, optimizing performance. Failover mechanisms enable automatic switching to backup servers if a primary server fails.

5. Sort data transmission with IoT cloud

For IoT software development, it is essential to consider critical aspects like data formatting, encoding, protocol selection, encryption, authentication, and error handling.

These factors inform the design and implementation of software components that facilitate secure and efficient data transmission and communication between IoT devices and the cloud.

To support this, you can do the following:

- Store received data in databases or data storage solutions within the cloud infrastructure, such as NoSQL databases (e.g., MongoDB) or time-series databases (e.g., InfluxDB).

- Backend services or applications can be built for managing and processing the stored data, incorporating functionalities like data analytics and integration with other systems.

- APIs or integration endpoints can be exposed to external systems or applications to enable interaction with the stored data. This allows data retrieval, updates, and integration with other enterprise systems.

6. Select the right hot and cold storage databases

Hot storage is used for frequently accessed data that requires fast read and write performance.

- You may require real-time data processing capabilities to monitor and control your IoT devices.

- In-memory databases like Redis or Apache Ignite can provide fast read and write performance, making them suitable for capturing and analyzing real-time data from IoT devices.

On the other hand, cold storage is used for long-term storage of less frequently accessed data, typically for analytical purposes.

- Data lakes like Apache Hadoop can be valuable as they offer scalable and cost-effective storage for large datasets.

- You can store IoT data in its raw form, allowing for flexible analysis and exploration.

Best practices for IoT software development

To develop IoT software that meets high standards, you must follow certain best practices for its optimal performance and integration within the IoT ecosystem. Here is what you should keep in mind:

- Evaluate accessibility requirements and ensure compatibility with different devices, screen sizes, and assistive technologies.

- Define the required functionality and features based on business needs and end-user requirements.

- Determine the budget constraints and allocate resources accordingly.

- Research and select the appropriate technology stack and development frameworks based on the chosen platform.

- Conduct thorough testing and quality assurance to ensure software reliability and performance.

- Create a well-defined development roadmap to track progress effectively, including milestones and deadlines.

- Provide ongoing support and maintenance to address issues, bugs, and user feedback post-launch.

Software development is an iterative process that often involves multiple revisions and optimizations to improve functionality, performance, and user experience. Deploy methodologies, such as Agile and Scrum, to better adapt to the changing requirements and deliver the desired end product.

Cloud connectivity and its importance in IoT software development

The purpose of an IoT solution is lost if it cannot connect and allow communication between things, people, and processes. Cloud connectivity ensures your IoT software performs as planned with minimum downtime. The following section will solve all your doubts about it:

Benefits of cloud connectivity in IoT software development:

- With tools like AWS IoT Device Management and Microsoft Azure IoT Hub, provisioning and configuring IoT devices becomes more streamlined. This enables rapid deployment, reduces time-to-market, and improves operational efficiency.

- It enables seamless and reliable communication between IoT devices and the cloud infrastructure. D2C communication allows devices to send data to the cloud for storage, analysis, and processing. On the other hand, C2D communication enables the cloud to send commands and updates back to the devices, facilitating remote management.

- Cloud connectivity enables OTA updates and commands for IoT devices. OTA updates allow for firmware upgrades and bug fixes without the need for physical access to the devices. This simplifies the update process and enhances device security.

Cloud services for IoT software development

Various cloud service providers offer dedicated platforms tailored specifically for IoT applications, namely:

1. Amazon Web Services (AWS) IoT Platform

AWS offers a suite of services aimed at IoT development, including AWS IoT Core, AWS IoT Device Management, and AWS IoT Analytics. It provides robust security features, including end-to-end encryption and access control for all data.

AWS also provides seamless integration with other AWS services like Lambda, S3, and DynamoDB, which can be used for data processing, storage, and analysis.

AWS IoT Device Management helps you scale your operations by allowing the registration, organization, and management of devices.

With AWS Greengrass, you can run local computing, messaging, data caching, sync, and ML inference capabilities for connected devices in a secure way.

2. Microsoft Azure IoT

With Azure IoT Hub, you can easily connect, monitor, and manage your IoT assets. It provides reliable and secure bi-directional communication between millions of IoT devices.

For device management, Azure IoT Hub provides built-in device provisioning, firmware update, and device twin capabilities. Azure IoT Edge allows you to deploy cloud workloads to run on IoT devices via standard containers.

Azure Stream Analytics on IoT Edge can also run real-time analytics locally on IoT devices. The availability of Azure AI and machine learning services further enriches IoT solutions.

3. Google Cloud IoT

With Cloud IoT Edge, you can deploy AI capabilities on gateway devices. Google provides a suite of fully managed and serverless Analytics services that seamlessly integrate with the IoT platform.

These services include BigQuery for SQL-like queries over terabytes of data, Cloud Pub/Sub for event-driven computing, and Cloud Functions for serverless data processing.

4. IBM Watson IoT

IBM Watson IoT Platform supports secure device connectivity and provides industry-leading capabilities such as edge analytics, end-to-end security, and various data management options.

With Watson IoT, you can create a cognitive IoT solution by integrating AI capabilities, which allows your IoT solution to understand, reason, learn, and interact.

The platform also offers risk management by providing threat intelligence, anomaly detection, and application security.

In addition, IBM Watson IoT is known for its ability to integrate legacy enterprise systems with new IoT deployments, making it a good choice for organizations looking to modernize existing systems.

Cost of data communication over the cloud and data management services

1. Data transfer costs

- Please check the pricing structure for inbound and outbound data transfers between your IoT devices and the cloud platform.

- Rates may vary based on the volume of data transferred, so evaluate the frequency and size of data payloads exchanged by your devices.

2. Message queuing services

- Evaluate if your cloud platform provides message queuing services for reliable message transmission.

- Some platforms may have separate pricing models for these services, so consider any associated costs.

3. Bandwidth consumption

- Higher data volumes or frequent data transmissions may result in increased costs, so factor in the expected usage patterns.

4. Cost optimization

- Explore options for data aggregation and filtering at the device level to reduce unnecessary data transfers.

- Consider leveraging edge computing to process data locally and minimize cloud-related costs.

Security in IoT cloud connectivity and communication

This one is important: ensure the cloud platform supports robust authentication mechanisms for IoT devices. This can include methods, such as:

Look for end-to-end encryption capabilities such as SSL/TLS or MQTT with TLS to provide secure data transmission, preventing unauthorized access or tampering.

Assess whether the cloud platform supports data encryption at rest and in transit. This ensures that your sensitive data remains protected when stored in the cloud and during transmission between devices and the cloud.

For example, if you are developing a connected healthcare solution that collects sensitive patient data, you would prioritize a cloud platform with strong authentication and encryption mechanisms to protect the privacy and confidentiality of the data.

Assess certificate installation methods for IoT device authentication in the selection of your IoT cloud platform

In the context of certificate installation on IoT devices, there are three possible scenarios to confirm:

1. You can install certificates on IoT devices before they are delivered

- In this scenario, you can pre-install certificates on your IoT devices before they are shipped or deployed.

- This allows for a streamlined device provisioning process, ensuring that devices securely authenticate when connecting to the IoT cloud platform.

2. End users or installers can use an app to install certificates on their IoT devices

- This scenario typically involves providing an application or tool enabling end-users or installers to install certificates on IoT devices.

- The app guides them through the certificate installation process, ensuring that the devices are properly authenticated and can establish secure connections with the IoT cloud platform.

3. End users cannot use an app to install certificates on their IoT devices

- In this scenario, end users or installers cannot directly install certificates on IoT devices due to technical limitations, security concerns, or specific business rules.

- In such cases, alternative authentication methods, such as username/password-based authentication or token-based authentication, can be explored to establish secure connections between the devices and the IoT cloud platform.

The choice of the certificate installation approach depends on:

- Your specific business requirements

- The level of control over the device provisioning process

- The technical capabilities and preferences of your end users or installers.

AWS IoT, for example, provides detailed documentation on IoT device provisioning and certificate management. By leveraging the capabilities offered by the IoT cloud platform, you can ensure secure authentication and establish trusted connections between your IoT devices and the cloud.

Authentication methods for cloud connections in an IoT ecosystem

Select one of the following approaches (AWS and Azure) based on hardware and firmware support, business rules, and feasibility:

A. Azure authentication methods

- Symmetric keys (shared access keys): This method uses a shared secret (password) to authenticate the device with the Azure IoT Hub. No certificate is required, and the device connects using a connection string or a Shared Access Signature (SAS) token password.

- X.509 self-signed certificates: This method involves using self-signed X.509 certificates to authenticate devices with the Azure IoT Hub. Each device has its own certification, and the Azure IoT Hub verifies its identity based on the certificate.

- X.509 Certificate Authority (CA)-signed certificates: This method utilizes certificates signed by a trusted CA to authenticate devices with the Azure IoT Hub. The certificates are issued by a trusted CA and verified by the Azure IoT Hub during authentication.

B. AWS authentication methods

- JITP (Just-in-Time Provisioning): JITP is an AWS IoT feature that provides devices with unique X.509 certificates during the first connection. AWS IoT Core generates and registers the certificates when a device connects for the first time.

- JITR (Just-in-Time Registration): JITR allows devices to be registered and provisioned in real-time upon initial connection. This method is primarily used when devices have pre-existing certificates issued by a trusted CA.

- Fleet provisioning: AWS IoT Core offers a customizable fleet provisioning template, a JSON document defining the provisioning workflow. This includes essential information like provisioning roles, policies, and certificates needed for devices. During provisioning, devices gain temporary service access via a bootstrap certificate. This feature is particularly valuable for large-scale device provisioning, enabling process automation and consistent security across all devices.

Always consult the official documentation the respective cloud platforms provide for detailed implementation guidelines and best practices.

Cloud costing considerations for IoT solutions

By carefully estimating the following parameters, you can make informed decisions about cloud costing in their IoT solutions:

1. Number of devices on the cloud

- Estimate the number of devices that will be connected to the cloud. Cloud providers often have pricing tiers or plans based on the number of devices or device connections.

- Determine the expected device count to calculate the associated costs accurately.

2. Frequency of data communication

- Define the frequency of data communication from D2C and C2D interactions. The more frequent the communication, the higher the potential costs.

- Consider your application’s requirements and balance real-time responsiveness and cost efficiency.

3. Data payload size

- Predefine the size of the data payload transmitted between devices and the cloud. Cloud providers often have minimum payload sizes that count as a single event for costing purposes.

- If your data payload exceeds the minimum size, there may be multiple events and incur higher costs.

For example, the device’s data payload size is 10KB, and the cloud’s minimum size for a single data payload is 8KB (counted as one event for costing). Sending a single message with a 10KB payload would count as two events, resulting in higher costs.

4. Required services for business use case

Determine the cost of additional services required to achieve your business use case within the IoT cloud platform. These services may include:

- Cold data storage: Assess the costs of storing infrequently accessed or archival data. Cloud providers often offer separate pricing models for cold storage to optimize costs.

- Server Virtual Machine (VM): Estimate the costs for running server VMs if needed for processing or hosting applications within the cloud platform.

- Analytic services: Consider the pricing of analytics services provided by the cloud platform, including real-time stream processing, batch analytics, and machine learning capabilities.

- IoT rule engine: Evaluate the costs of using rule engines to implement business logic and automate actions based on predefined conditions.

- Relational database: Estimate the costs for storing and querying data using relational database services offered by the cloud platform.

IoT POC and prototype development

Implementing IoT technology as an OEM involves the development of proof of concept (POC) and prototypes to validate the feasibility and functionality of your IoT solution. In this section, we will outline the critical steps involved in the process, address the challenges faced by OEMs, and offer practical solutions:

1. Brainstorm and list your requirements

Engage with stakeholders

- Conduct interviews or workshops with engineers, designers, and end-users to gather their input.

- Ask specific questions to understand their pain points, desired features, and expectations.

- Create personas or user profiles to capture user needs and preferences.

Define the scope

- Break down the goals and objectives into specific, measurable targets.

- Prioritize the requirements based on their importance and feasibility.

- Create a detailed requirements document that includes functional and non-functional requirements.

2. Define a product design and technical strategy

Architecture and components

- Create architectural diagrams illustrating the hardware components, such as sensors, actuators, and communication modules, as well as the software components, including cloud services and data processing layers.

- Determine the necessary interfaces and protocols for communication between components.

Technical strategy

- Research and evaluate different hardware options, considering cost, power consumption, and compatibility with your requirements.

- Select appropriate sensors and determine how they will be integrated into the system.

- Choose the best connectivity options, such as WiFi, Bluetooth, or cellular networks, based on the use cases and environmental constraints.

- Plan for data management, including data storage, processing, and analytics.

3. Sort out tech stack selection and development

Technology stack

- Research available programming languages, frameworks, and libraries suitable for your IoT solution.

- Consider the scalability and support of each technology choice.

- Evaluate the compatibility of the technology stack with the chosen hardware and connectivity options.

IoT development platforms or frameworks

- Assess different IoT platforms or frameworks that align with your requirements.

- Compare their features, ease of integration, and community support.

- Consider factors like cloud services, device management, and analytics capabilities.

Software component development

- Break down the development tasks into smaller modules or components.

- Design and develop device firmware, ensuring proper communication with sensors and actuators.

- Develop the back-end infrastructure for data processing, storage, and communication.

- Design user interfaces for device control and data visualization.

4. Launch your prototype

Build a functional prototype.

- Assemble the selected hardware components and ensure their proper integration.

- Develop and deploy the software components onto the prototype devices.

- Configure the prototype for initial testing and data collection.

Controlled testing

- Create test cases based on the defined requirements and use cases.

- Perform functional testing to verify if the prototype meets the expected functionality.

- Validate the performance of the prototype under different conditions.

Thorough testing

- Conduct performance testing to assess the scalability and response times of the prototype.

- Perform security testing to identify potential vulnerabilities and implement appropriate countermeasures.

5. Evaluate your results

Data analysis

- Analyze the collected data to gain insights into performance, user behavior, and system interactions.

- Use visualization techniques to interpret the data effectively.

Performance assessment

- Compare the performance metrics of the prototype against the defined goals and objectives.

- Identify areas where the prototype excels and areas that need improvement.

Stakeholder feedback

- Gather feedback through surveys, interviews, or usability testing sessions.

- Incorporate the feedback to refine and enhance the prototype.

- Use the feedback to prioritize the features and improvements for further development iterations.

In conclusion

Deploying IoT in your systems and processes as an OEM can be complex, but it offers tremendous opportunities for growth, innovation, and customer value. At Intuz, an IoT app development company, we specialize in providing IoT solutions and consulting services tailored to the specific needs of OEMs.

We have worked with global brands such as Speck Pumps and Jibu, helping them build a consumer IoT solution for pool equipment automation and enterprise-level fuel station operations management, respectively.

We have the necessary skills and experience across industries to tailor our IoT solutions to your specific needs, ensuring they align with your business goals and industry requirements. Our dedicated team can assist and address any concerns throughout the implementation process and beyond.

So, take the first step towards transforming your OEM operations with IoT technology. Contact us today, and let us be your trusted partner in the world of IoT.