Table of Content

IoT is rightfully defined as a system of interconnected computing devices and machines that transmit data over a communication network - without human interaction. In the past decade, IoT has changed how we function - from a business and personal perspective - as it enables real-time status monitoring.

Merge IoT technology with the ever-evolving AI, and we have a system that enables companies to predict changes and optimize their devices more naturally.

But how do IoT and AI work together? Is it not a bit odd to see two differential technologies operate in sync and not butt heads? Well, IoT and AI are indeed two different technological advancements that are reshaping industries worldwide in their way. However, their benefits increase when used together.

IoT can link gadgets, modules, and processors, acting as a nervous system-like signaling mechanism. Conversely, AI can function like a brain, gathering, processing, and memorizing data on the go. AI uses the data sets to drive the system-wide choices in real-time.

Together, the two create a new technology - AIoT, which comprises smart interconnected systems that can self-correct and self-heal. Now, let us understand the concept in greater detail, along with its benefits and use cases in today's world.

What is AIOT?

The term AIoT blends IoT connectivity with AI-driven deep learning and advanced analytics. This cutting-edge technology is founded by incorporating AI into IoT infrastructures, amplifying data value many times.

AIoT enables an algorithm that improves communication and applies predictive capabilities to give businesses a competitive edge. Simply put, the data gathered by distributed nodes fuses AI and IoT using AI techniques such as machine learning and deep learning.

Machine learning capabilities, for instance, are subsequently placed nearer the data source. Edge AI, also known as Edge Intelligence or edge computing, is a notion that enables greater scalability, resilience, and efficiency in the systems in question.

IoT and AI: An amalgamation you did not know you needed

The real-time processing of data gathered by IoT solutions is the primary reason AI capabilities are used in this scenario. As a result, IoT connectivity and data transfer prowess are integrated with machine learning models in AI systems.

In other words, by merging AI with IoT, the latter can function beyond information gathering and conveyance. IoT devices can also comprehend and evaluate the data fetched better.

In a nutshell, IoT and AI can fundamentally alter how businesses, industries, and economies function. AI skills supplemented with IoT technology create smart machines that can make decisions with little human involvement.

Combining these two streams benefits both industry experts and businesses to a great extent. IoT is concerned with devices communicating through the internet, but AI allows these "things" to learn from the data over a while.

In other words, IoT and AI are two different technologies that significantly impact businesses through a smarter yet connected system. While IoT is the primary body, AI serves as the brain, making choices that regulate the body's functioning.

Let's Integrate AI and IoT for Smarter Solutions!

Let's Get StartedKey factors influencing the success of AIoT

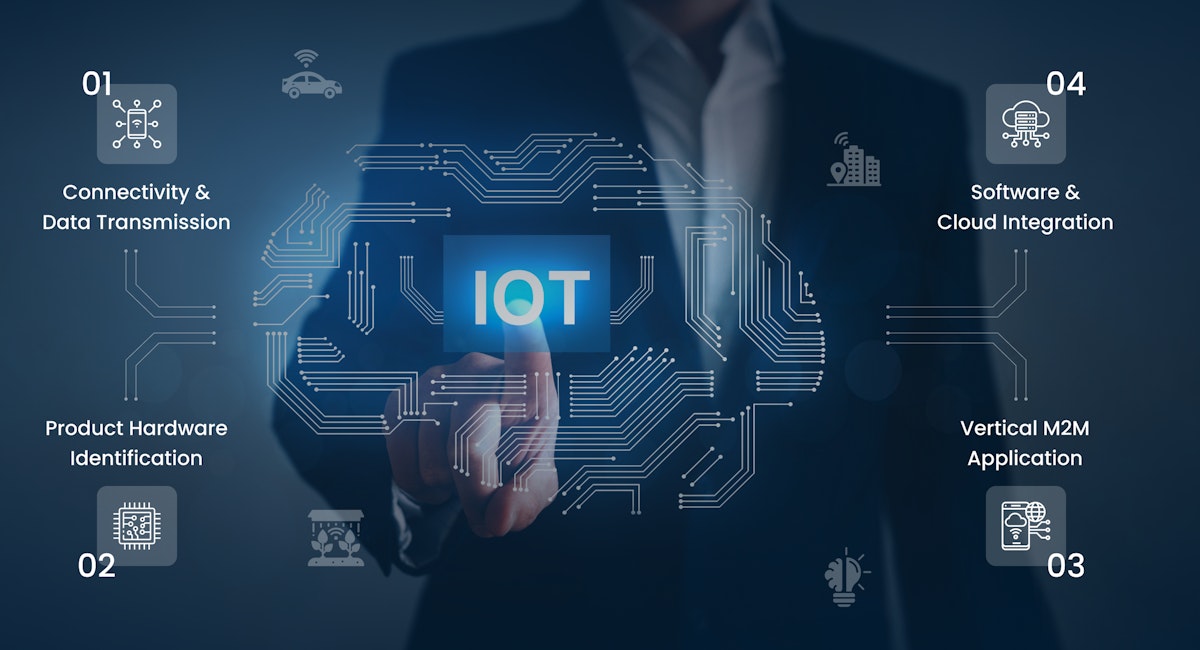

Regardless of the industry niche, it is essential to process high volumes of enormous data sets produced from IoT devices, which will help gain valuable insights, real-time monitoring, reduced maintenance cost, and enhanced user experience. The following are the critical factors for the success of AIoT:

1. Data collection

The IoT-connected system must gather data from numerous devices to train the AI model to find flaws, correct them, and eliminate biases while processing data in the long run.

2. Training

Advanced neural networks and various training procedures are frequently needed in AI models. The arrangement necessitates more powerful processing capacities in tools and machinery. As a result, it can support and conduct parallel operations and analyze more significant data volumes.

3. Inferencing

Finally, the trained AI model generates inferences and predictive insights. As a result, AI models can increase and improve their data collection, processing, and analysis efficiency.

Top use cases of AIoT

The applications of augmented AIoT technology cover personal devices, end-user computers, enterprise machinery, and so on. In the consumer space, AI and IoT have found a home in security cameras, smart appliances, and home management systems, such as the thermostat.

By connecting these machines together and adding a certain level of intelligence, product users can better understand what they need. That is what AIoT is all about! Let us take a look at seven widespread use cases of AIoT technology:

1. Video surveillance

Incorporating AI and IoT makes video surveillance for security purposes a lot more efficient and smart. Regarding traditional Video Management Systems (VMS), human operators are required to watch multiple video feeds.

This means that the video content depends on limited attentiveness, subjective judgment, and splotchy reaction times. AIoT, on leveraging machine learning algorithms, analyzes the video feeds in real-time, detects objects, and objectively recognizes people and events.

Smart Video Surveillance is extremely useful in retail. For instance, American supermarket giant Walmart utilizes image recognition camera technologies at checkouts to detect theft. Other deep learning security apps include intrusion event detection and weapons detection.

2. Inventory management

You may manage inventories with an integrated AI and IoT platform at several manufacturing facilities. It is equipped with analytical capabilities suitable for various use cases. One can enhance resource forecasting and JIT inventory management solutions.

3. Predictive maintenance

It involves tapping into advanced analytics-based manufacturing use cases for AI and IoT. You may use machine data to create applications that let you check the condition of assets and pinpoint service requirements.

It keeps you informed throughout the asset lifecycle, and you only need to conduct inspections and repairs when there is an emergency. It minimizes instances of unplanned outages and unexpected maintenance expenses.

By making your asset operating environments ideal, you maximize your performance and extend the equipment's life. Predictive maintenance is not just about controlling maintenance timings and expenditures.

It also enables you to make room for additional enhancements, do further research, and fully resolve production-related difficulties before they hamper production and burn a hole in your pocket.

IoT Protocols: Making IoT Data Communication Seamless

Learn More4. Supply chain management

AIoT enables dynamic supply chains by increasing transparency and control over the caliber of supplier outputs. It allows end-to-end asset tracking throughout the supply chain along with route optimization for optimal delivery and shipment.

5. Robust asset management

Knowing how your assets perform compared to your KPIs helps you improve their performance and operational efficiency. You can also determine whether your current KPIs are relevant.

You can quickly react to abnormal asset behavior with performance management apps developed directly on the AIoT platform. Setting a trigger will allow the platform to send you automated warnings anytime a deviation occurs.

Additionally, you can improve your KPIs thanks to real-time machine data feedback. By doing this, you can maximize the performance of your systems - resulting in quicker production times and more efficient use of your resources.

6. Energy consumption management

You may reduce your energy usage by utilizing the most energy-efficient alternatives for your connected assets. You can pinpoint areas for development and track energy usage over time with AIoT.

The technology helps you spot patterns and stop unusual energy leakage. Additionally, you can monitor energy peaks, investigate strategies to reduce energy waste, and understand how each industrial asset affects overall energy consumption.

AIoT significantly increases the environmental consciousness of your smart manufacturing activities across all production units. You can use the data to start making efforts to lessen the strain that industrial operations have on the environment.

7. Real-time machinery condition monitoring

Your data flows in one direction as soon as you connect your devices to the platform. That is the only source of truth you have. With AIoT you can monitor variables such as temperature, moisture, and light across manufacturing sites.

To stay on top of all the intricacies surrounding the operations, you also monitor pre-defined KPIs. Additionally, you configure automated warnings for when assets perform poorly or when particular parameters are surpassed.

AIoT helps with predictive maintenance, enabling you to identify errors quickly, take corrective action, and reduce machinery downtime.

AIoT platforms assist you in allowing increased transparency in asset performance, both locally and across manufacturing locations, by fusing IoT with solid data analytics.

Advantages of AIoT

Incorporating AI and IoT technologies comes from the rise of many diverse applications and flexibility in use. AIoT promotes and provides actionable options. While IoT can give you information about the devices, you can predict decisions and outcomes by applying machine learning algorithms, which are a part of AI. Here are the top benefits of using AIoT:

Advantages of AIoT

1. Greater risk management

Across all industries, risk management is crucial for organizations. Distributed, smart systems are capable of foreseeing risks in the future and even implementing preventative steps, thereby bringing repair expenses and maintenance costs down.

Examples include crowd analysis in public spaces, employee safety analysis on the factory floor, and analysis of water levels in a Smarty City.

Organizations can stay ahead of the game in anticipating and managing potential dangers in the future with the aid of AIoT technologies. Insurers have recently started using these apps to control insurance risks for individual machines and entire factories.

2. Reduced operational costs

When you put good technology to use, you automatically work towards decreasing unnecessary expenses in the long run. For instance, more efficient use of resources is made possible by developing intelligent systems. An example is applications for smart buildings that alter temperature and light controls based on occupancy.

AIoT devices are essential for analyzing machinery and preventive maintenance using smart factory applications in smart factories. You can prevent equipment failure and costly business interruptions as sensors and cameras identify and monitor the status of machine parts.

3. Superior customer experience

AIoT allows you to comprehend the challenges faced by your customers and their changing behaviors and preferences.

For instance, AIoT gathers inventory data in the retail sector to determine which aisles need to be quickly restocked, which products are selling like hot cakes, and which galleries have received zero consumer visits.

Retail businesses can, therefore, correctly predict customer habits and provide a more holistic experience thanks to the IoT data fetched and processed.

4. Enhanced operational efficiency

Enterprises can restructure their operational procedures using intelligent automation. Smart environmental sensors, for instance, can detect how many people are safe within office buildings and transmit that information to the IoT device or the central data hub.

Remotely monitoring the physical security processes of an office building is made possible by incorporating human facial recognition software and other biometric access devices. Businesses can attain the highest level of operational efficiency using AIoT.

Machine learning techniques can be used by AIoT-enabled devices to create, analyze, and recognize patterns in data. As a result, it may swiftly offer operational insights, identify and resolve issues, and automate manual procedures.

Therefore, organizations can provide better services with an optimized workforce as AI handles repetitive jobs. The automation of vision-based quality control and cameras for quality assurance in industrial automation are two powerful examples. Several programs work to monitor and guarantee adherence to rules and norms.

5. Real-time analytics and monitoring

Systems monitoring in real-time can help you save time and reduce costly business interruptions. It includes ongoing machine monitoring to find abnormalities and predict or decide the next steps based on them.

It minimizes human involvement while producing quicker and more precise outcomes. Using sensors for leak detection is one application of AIoT technology in the oil and gas industry. It enables remote monitoring and control of inventory.

Six real-life examples of AIOT

AI and IoT make devices more accessible and do not let any gathered data sets go to waste. Businesses can tap into their full potential when they have two powerful technologies at their disposal. Here are six real-life examples of AIoT:

1. London City Airport

The first airport to integrate AI, IoT, and cross-technology networking, London City Airport monitors every aspect of the facility and gives passengers accurate information about flight statuses. The cabin crew can monitor passenger location, boarding queue activity, gate information updates, baggage tracking, and other crucial activities through IoT devices.

The airport is equipped with a reliable IoT digital engine model that includes Industrial IoT (IIoT) protocols, Constrained Application Protocol (CoAP), Web Sockets, and Application Program Interfaces (APIs). It efficiently speeds up business delivery with IoT dashboard and Business Intelligence (BI) solutions.

2. Boston Dynamic Spot

The industrial sector is well known for utilizing futuristic technologies to streamline its operations. Some of the newest initiatives in Industry 4.0 include robotics.

More particularly, robots are now adapting to the contemporary demands of factories and offering wiser solutions to enhance operational efficiency.

Robots have, therefore, become smarter and more responsive to different processes as a result of the development of the AIoT. The Spot is one of many robotic systems that the American engineering and robotics design company Boston Dynamics has unveiled.

It is a quick, mobile robot that can move through different terrains with unprecedented agility, automate inspection tasks, and collect data securely. It offers a fantastic way to execute things more predictably and effectively in factories.

3. Self-driven cars by Tesla

Tesla's cars use "Autopilot," a leading-edge driver assistance technology. The vehicles have robust onboard computers, external cameras, and ultrasonic sensors for data collection.

The data is examined in a deep neural network model, helping the automobile decide what action to perform next. Tesla has made great strides in its self-driving capabilities by introducing the "Autopilot" technology.

Tesla's invention does not come as a surprise as hands-free driving is viewed as the next logical step in automotive - making driving safer and less stressful. A significant area of growth for AIoT is the use of self-driving cars on public roads.

4. ET City Brain

This is a technology-driven AI developed by Alibaba Cloud, which maximizes the use of metropolitan public resources. The system processes video logs and data streams from various machines and sensors across an urban center using big data and deep neural networks. When it was initially put into practice in Hangzhou, China:

- The incident identification accuracy rate increased to 92%. This accelerated reporting of accidents and sped up emergency responses.

- In Xiaoshan district, the traffic signal automation resulted in a 3-minute reduction in daily commuting time and a 15% increase in travel speed.

- Ambulance arrival times were cut in half, enabling help to arrive at their destination seven minutes earlier.

5. Amazon GO

The concept store "Amazon Go" is revolutionizing the retail sector. It enables customers to enter establishments, pick up an item, and proceed without worrying about payments. Amazon Go stores do not have cashiers but IoT devices that auto-deduct money from the user's e-wallet.

Additionally, AIoT automatically deletes items from the users' carts when they return them after picking them up. Scanning the products in their cart, the system calculates and processes the payable amount when they exit. As a result, AIoT has simplified the shopping experience, optimizing the customer journey.

6. Walmart

As the largest retail chain in the world, Walmart leverages the assistance of AI and machine learning combined with IoT. Walmart uses it to manage more than 11,000 physical stores and an equal number of online stores for each county or state. Cross-technology solutions, voice-based Google Assistant search, and facial recognition capabilities have helped the retail sector expand higher revenues while delivering more customer value.

Get a Free Roadmap Leveraging AIOT for Your Business!

Book Free ConsultationWhat is next in the world of AIoT? Growth!

AIoT uses the power and efficiency of both AI and IoT, thereby making the technology suitable for specific problems associated with distributed smart systems. From oil and gas and retail to manufacturing and healthcare to banking and insurance, many industries are leveraging the power of AIoT.

At Intuz, we enable companies across verticals to check out AIoT app development that serves specific purposes. If you would like to know how you can dip your toes into the AIoT technology pool, get started with us today!