Table of Content

The chemical industry is highly diverse and responsible for manufacturing a wide range of essential components for both consumer and industrial products across sectors, including agriculture, automotive, construction, and pharmaceuticals. With annual sales of $5 trillion and over 20 million employees, this sector indeed plays a critical role in the global economy.

Moreover, Industry 4.0 is expected to bring significant changes as it integrates digital and physical advanced technologies, such as the Internet of Things (IoT), advanced analytics, and robotics, into the chemical industry's core manufacturing processes.

IoT gives the productivity of chemical plants a boost through process control, predictive asset management, and production simulations. But before we discuss the benefits of IoT for the chemical industry, let us look at what is stalling the sector growth:

Operational challenges in the chemical industry

In the last few years, this sector has undergone a consolidation phase, placing much emphasis on environmental regulations that led to the closure of plants engaged in unsustainable practices. Besides, there are several common challenges resulting from the global nature of its value chain, including:

1. Costly batch scrapping or reworking

In the chemical industry, it is common for batches to fail to meet quality standards or customer specifications, necessitating their scrapping or reworking. This can result in increased costs, wasted materials, delayed delivery, and reduced customer satisfaction, which is frustrating for all the stakeholders involved.

While scrapping a batch is the least desirable option since it leads to no financial gain, and the chemical company must bear the manufacturing costs, reworking the batch involves combining the original overhead, materials, and labor costs with additional charges incurred in making the required adjustments to meet quality standards.

2. Faulty quality control

Maintaining consistent quality in the chemical manufacturing process is essential as it ensures the safety, effectiveness, performance, and compliance of the products produced, from raw materials to finished goods.

Quality control includes checking incoming materials, tracking standing inventory, and inspecting batches of the finished product.

Those chemical companies that do not do adequate R&D during formulation and track and compare the results of their research, formula changes, and outcomes end up with substandard batches that can put human life at risk and increase business expenses.

Transform Your Chemical Processes with Smart IoT Integration!

Let's Get Started!3. Chaotic formula management

Formula management is a complex task that involves creating, storing, and managing chemical formulas for products. Precise formulations are required for many chemical products to ensure their quality and performance. Chemical companies face challenges such as changing customer demands, evolving regulations, fluctuating raw material prices and availability, and competitive pressures in managing these formulas.

4. Botched supply chain management

Chemical manufacturers rely heavily on a steady and consistent supply of raw materials and other supplies to keep their production lines running smoothly. Any disruptions in the supply chain can have a significant impact on production schedules and cause delays, which can result in lost revenue and decreased customer satisfaction.

The recent global semiconductor shortage is a prime example of how disruptions in the supply chain can impact the chemical industry. Semiconductors are used in various electronic components critical to the industry, such as sensors, controllers, and other electronic devices used in production processes.

As the global demand for semiconductors increased, supply chain disruptions caused by the COVID-19 pandemic, trade restrictions, and other factors led to a shortage in supply, which has had a ripple effect on the chemical industry, causing delays in producing electronic components and other products relying on semiconductors.

IoT Operational Technology (OT): Convergence With IT & Key Differences

Learn More5. Poor inventory visibility

Real-time information on raw materials and finished products is often caused by various factors, including inaccurate data entry or tracking systems, high demand variability, long lead times, and supply chain disruptions.

In some cases, chemical companies may have multiple production sites and warehouses, making it challenging to keep up with inventory use and monitor stock levels accurately.

A lack of inventory visibility impacts their ability to manage stock levels effectively, resulting in stockouts and delays in product delivery, leading to dissatisfied customers and lost sales.

6. Zero hazard analysis

Hazard analysis involves identifying potential gas or chemical hazards in the workplace, such as leaks from cylinders, pipes, tanks, and valves, and assessing the potential impact on workers' health and safety, as well as the environment and property.

Companies that do not do hazard analysis miss out on the data collected essential for ensuring compliance with regulatory agencies such as the EPA and tracking the chemical industry's carbon footprint.

7. Robust equipment management

Managing equipment involves the maintenance and upkeep of specialized machinery and vital components used in chemical production.

This process can be challenging and resource-intensive due to various factors such as aging equipment, high levels of wear-and-tear, frequent breakdowns or malfunctions, lack of available spare parts or skilled technicians, and strict regulatory compliance requirements.

How IoT technology improves the chemical manufacturing process

Chemical companies can utilize IoT to improve operations and gain positive business outcomes. The IoT can empower them to gather and analyze data from multiple sources, including sensors and devices, to make data-driven decisions and optimize their processes.

Let us explore seven critical functions of smart manufacturing with IoT in the chemical industry:

1. Automated supply chain

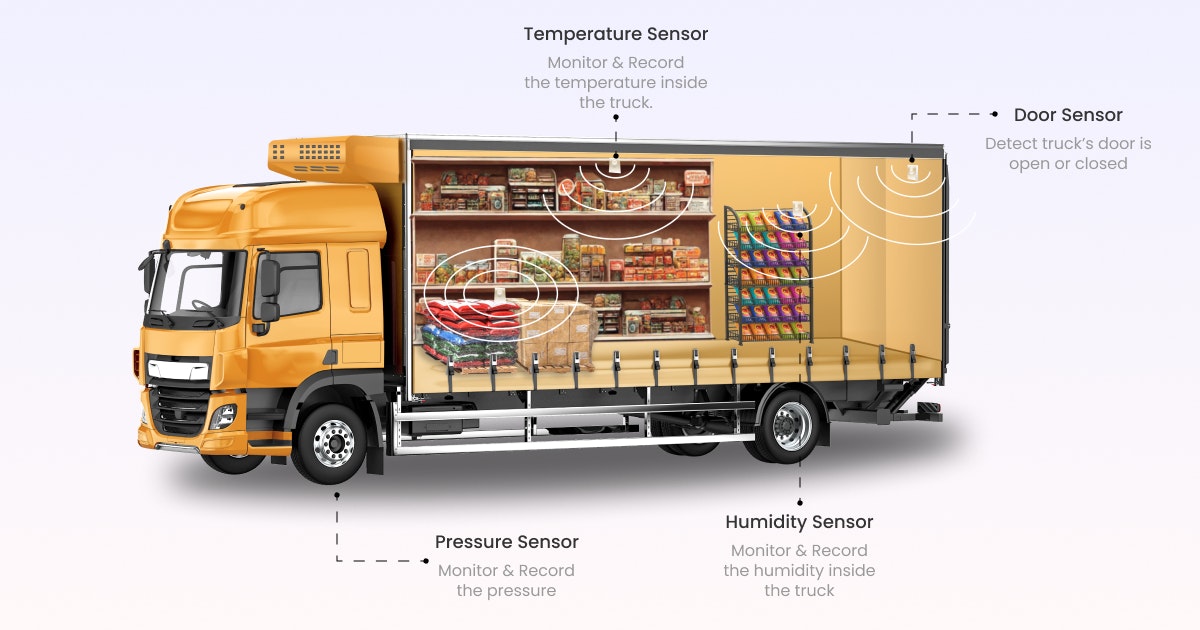

Automating the supply chain using IoT technology can benefit chemical companies, including real-time visibility into inventory levels and shipping status.

IoT sensors, placed on products and packaging, track their location and condition and allow companies to monitor the movement of goods throughout the supply chain. This will enable them to prevent theft, damage, and loss of goods.

Moreover, chemical companies can forecast demand and optimize inventory levels with predictive analytics. They can better understand customer demand and adjust their inventory levels by analyzing historical sales data, market trends, and other relevant factors.

Another benefit of automating the supply chain is the ability to identify potential supply chain disruptions before they occur. By monitoring the status of shipments in real-time, chemical companies can identify delays or other issues and take corrective action before they become significant problems.

2. Real-time inventory management for chemicals

This is crucial for chemical companies to ensure they have the necessary raw materials and supplies to meet production demands. IoT devices can provide real-time data on inventory levels, which can authorize companies to avoid stockouts and delays - positively impacting production schedules.

IoT sensors can track the location and movement of inventory, providing real-time visibility into the supply chain and helping chemical companies optimize inventory levels, reduce lead times, and avoid stockouts. This improves customer satisfaction by ensuring that orders are delivered on time and in full.

3. Chemical hazards prevention

Besides detecting gas or chemical leaks, IoT sensors can monitor other safety hazards in the workplace, such as high levels of noise or vibrations that could harm workers' hearing or cause equipment damage. IoT can also determine high levels of radiation or electromagnetic fields that could - again - pose a risk to workers' health.

Moreover, IoT sensors help track workers' movements and activities in real time. They can identify potential safety risks and hazards, such as workers entering restricted areas or operating machinery without proper training or equipment.

IoT technology enables chemical companies to prioritize safety and prevent accidents and injuries in the workplace. By determining and mitigating hazards in real time, they can create a safer work environment for employees and minimize the risk of costly lawsuits and damage to their reputations.

Cutting-edge Industrial IoT Solutions and Development Services Company

Explore now4. Consistent quality monitoring

Quality monitoring is critical in the chemical industry, where even small variations in the composition or purity of products can lead to significant problems, including reduced product performance, customer dissatisfaction, and even safety risks.

By using IoT applications in the chemical industry, companies can monitor and control the quality of their materials and products more effectively. For example, sensors can be installed in the production equipment to measure critical process parameters such as temperature, pressure, and pH levels.

This data can be collected and analyzed in real-time to identify deviations from established quality standards. If an issue is detected, the system can automatically adjust the process or alert operators to take suitable action.

Similarly, IoT sensors can monitor the quality of raw materials and finished products. For example, RFID tags can track the movement of materials and products throughout the supply chain, providing real-time visibility into their location and condition.

Temperature and humidity sensors can monitor storage conditions, ensuring that materials and products are not exposed to conditions that could affect their quality.

By leveraging IoT use cases in the chemical industry, companies can achieve more precise and consistent quality monitoring, reducing the risk of defects, rework, and customer complaints. They can also ensure compliance with regulatory standards and build a stronger reputation for quality and reliability.

5. Prompt raw materials tracking

In addition to monitoring the quality of chemical products, IoT sensors track the location and movement of raw materials and finished products in real-time. This is crucial for chemical companies that must manage complex supply chains with multiple suppliers, production sites, and distribution centers.

With real-time tracking, they can quickly identify any delays or disruptions in the supply chain and take proactive measures to avoid production delays or stockouts.

IoT sensors also optimize inventory levels by providing accurate and timely data on material usage and consumption. This helps reduce inventory holding costs while ensuring the company has enough raw materials to meet production demand.

6. IoT-driven formula management

Innovative formula management tracks the usage of raw materials and inventory levels, as well as enables real-time adjustments to formulas based on changes in the availability or pricing of materials. This enables chemical companies to optimize their supply chain and reduce costs while maintaining the desired quality and performance of their products.

Additionally, IoT devices can monitor the performance of equipment and machinery used in the formulation process. This helps identify any issues or potential malfunctions before they become significant problems, reducing downtime and improving efficiency.

7. Predictive equipment management

A cloud-based system for equipment management in chemical production utilizes IoT sensors to collect real-time data on the condition of machines, including temperature, pressure, and vibration. Cloud-based systems can analyze this data to predict and prevent breakdowns or malfunctions, optimize maintenance schedules, and order spare parts when needed.

Additionally, the system can track and document maintenance and inspection activities, resulting in reduced downtime, increased productivity, and improved safety in the workplace.

How IoT is Solving OEMs' Challenges in Steel Manufacturing

Explore NowOver to you

Overall, the IoT can help chemical companies drive game-changing outcomes, do more with less, empower employees through process automation, deliver a best-in-class customer experience, and invent new business models and revenue streams.

It is just that the availability of clean and abundant data and highly skilled data scientists is crucial for success in this endeavor. Without these resources, the rapid adoption of smart manufacturing with IoT in the chemical industry may be hindered.

Ultimately, the technology’s potential benefits make it a worthwhile investment for those seeking to meet the evolving needs of their stakeholders and customers.

If you want to build an IoT application for your business, book a free consultation with our experts today.