Table of Content

Water is an indispensable resource for various general, commercial, and industrial applications. However, only a tiny fraction of the water on the earth’s surface is consumable. This highlights the need to implement treated water as an alternative to meet global water demands.

Many industries use freshwater as a coolant and solvent to enhance the quality of their products but discharge the used water into the environment, which, in turn, severely contaminates it.

Implementing an IoT-powered water quality monitoring system, in particular, can accurately and timely reflect the current water quality and development trend, providing a scientific basis for water treatment projects.

The need for monitoring parameters in water treatment plants

Most manufacturers generate wastewater that contains chemical, biological, and physical contaminants harmful to plant and animal life in affected environments. Monitoring parameters in water treatment plants helps ensure compliance with strict regulations and guidelines that dictate the acceptable levels of safe and quality water being provided to the public.

It can help manufacturers optimize the treatment process to ensure the water is treated as efficiently as possible. For example, by monitoring the pH of the water, they can adjust the dosage of chemicals to ensure that the water is appropriately treated. Adding to that, here is a brief explanation of each parameter and its significance in water treatment.

- Temperature affects the rate of chemical reactions in the treatment and the solubility of certain chemicals, which is responsible for the effectiveness of the treatment process.

- pH measures the water alkalinity or acidity. The pH of the water impacts the stability of the water distribution system.

- Dissolved Oxygen (DO) is essential for maintaining the health of aquatic organisms in the water.

- The density of wastewater influences the sedimentation process deployed in water treatment plants.

- The density of wastewater influences the sedimentation process deployed in water treatment plants.

- Ammonia is a common pollutant in wastewater and can be toxic to aquatic life. It is typically removed through biological treatment processes.

- Conductivity - as the name suggests - defines the ability of the water to conduct electricity. It can indicate the presence of dissolved salts, known for the corrosion of pipes.

- Titration is a chemical process used to determine the concentration of certain chemicals in water.

- Turbidity determines the cloudiness of the water. High turbidity can indicate the presence of suspended solids that attack the clarity of the water.

Streamline Your Water Treatment Processes with Custom IoT Solutions!

Explore SolutionsIoT in water treatment: Challenges with different parameters

Water treatment involves several processes to remove impurities and contaminants from water and make it safe for consumption. However, many challenges are associated with different parameters in water treatment that manufacturers must know about, including:

1. Corrosion

Low pH levels are responsible for the corrosion of pipes and equipment, boosting maintenance costs and downtime. Corrosion can also release heavy metals and other contaminants into the water, thus polluting it.

2. High turbidity

High turbidity levels can make removing pathogens from the water difficult, posing a risk to public health. They are also responsible for heavy metals in water, which can be costly and time-consuming to remove. Heavy metals such as lead and mercury can risk public health if present at high levels.

3. Deflocculation

Deflocculation occurs when suspended particles in the water start clumping together, which can cause high effluent Total Suspended Solids (TSS) levels. This increases algae growth, which is not great for water quality and the environment.

4. Clogged water filters

As water passes through treatment, particles, and contaminants are removed through various filtration methods. Over time, these filters can become clogged, reducing flow rates, surging backwash frequency, and increasing maintenance costs.

5. Disinfection inefficiency

Disinfection is an essential step in water treatment to remove any remaining pathogens or bacteria, and low DO levels can make this process less effective.

6. Temperature instability

Higher water temperatures can promote the growth of bacteria, viruses, and other microorganisms, reducing water quality and increasing the risk of waterborne illnesses.

Plus, some chemical reactions that occur during the water treatment process can be temperature-dependent. For example, the formation of disinfection byproducts increases at higher temperatures, which affects the water taste and smell and potentially pose health risks.

7. Excessive sludge disposal

As the water is treated, sludge is generated, which can accumulate and pose a risk to the environment if not properly handled. This boosts disposal costs and impacts water quality.

8. Unbalanced pH of the water

This affects the efficiency of the plant and may lead to increased operating costs. In addition, high or low pH levels create an environment where bacteria can thrive, impacting water quality.

9. High nitrate and ammonia content

High nitrate and ammonia levels in treated effluent can lead to environmental problems such as eutrophication and harmful algal blooms. Eutrophication is the process by which excess nutrients in the water (like nitrate and ammonia) can result in the overgrowth of aquatic plants and algae, thereby depleting water oxygen and harming marine life.

10. Increased risk of bacterial growth

Bacterial growth occurs if the water is not properly disinfected or disinfection is impractical. This can result in a higher risk of waterborne illness or disease transmission.

11. Residual chemicals after treatment

Some chemicals may not be completely removed during treatment, posing a risk to public health if present in the drinking water. Therefore, monitoring and testing the water regularly is essential to ensure any residual chemicals are within acceptable levels.

Types of sensors used in an IoT water treatment solution

A water quality sensor merely detects various water parameters, including pH, residual chlorine, turbidity, suspended solids, COD, BOD, conductivity, and dissolved oxygen. These sensors utilize multiple methods, such as chemical, physical, and biological reactions, to obtain accurate water quality data for manufacturers, researchers, and engineers.

Water quality sensors, such as the following, are helpful in various applications, including laboratory research, environmental management improvement, marine water quality assessment, hydraulic model calibration, and sewage treatment:

1. PH sensor

2. COD sensor

3. ORP sensor

4. Turbidity sensor

5. Chlorophyll sensor

6. Conductivity sensor

7. Blue-green algae sensor

8. Residual chlorine sensor

9. Ammonia nitrogen ion sensor

10. Dissolved Oxygen (DO) sensor

These sensors play a crucial role in monitoring water quality and accumulating data to take proactive action. For example, pH monitoring in water treatment happens by measuring the potential difference between a pH electrode and a reference electrode.

Sensors like COD and OPR determine the amount of organic pollutants present in water and the level of oxidative or reductive properties of a solution respectively. Turbidity sensors detect suspended particles such as sediment, algae, and bacteria in the plants.

The chlorophyll sensor uses the fluorescence method to measure chlorophyll concentrations between 0 to 200 μg/L in the water to keep eutrophication and harmful algal blooms at bay. On the other hand, conductivity sensors detect the presence of contaminants such as dissolved solids to enable water purification post analysis.

The blue-green algae sensor utilizes the fluorescence method to measure blue-green algae concentrations between 0 to 100 μg/L in the water for further treatment. A DO sensor determines the amount of oxygen dissolved in a liquid, usually water.

The ammonia nitrogen ion sensor uses the ion-selective electrode method to compute ammonia nitrogen ion concentrations between 0.01 to 1000 mg/L, while a residual chlorine sensor is vital in ensuring the water is safe for consumption.

Functionalities present in an IoT solution for water treatment

As you know - IoT solutions can provide many functionalities that enable water treatment plants to optimize their operations, reduce energy consumption, conserve water, and improve water quality while ensuring compliance with regulatory standards. Here are the functionalities one can typically leverage:

1. Automated temperature control using IoT

This functionality in an IoT solution for water treatment allows the treatment plant to maintain a constant temperature range without requiring constant manual intervention. This means that the temperature of the treated water can be controlled automatically by the IoT solution, based on the desired set point, without operators needing to manually adjust the temperature.

The IoT solution achieves this by deploying sensors to continuously monitor the temperature of the water at different points in the treatment process and then using this data to adjust the temperature of the water as needed automatically.

For example, if the water temperature is too high, the IoT solution may activate a chiller to cool the water, or if the temperature is too low, it may activate a heater to warm the water instead.

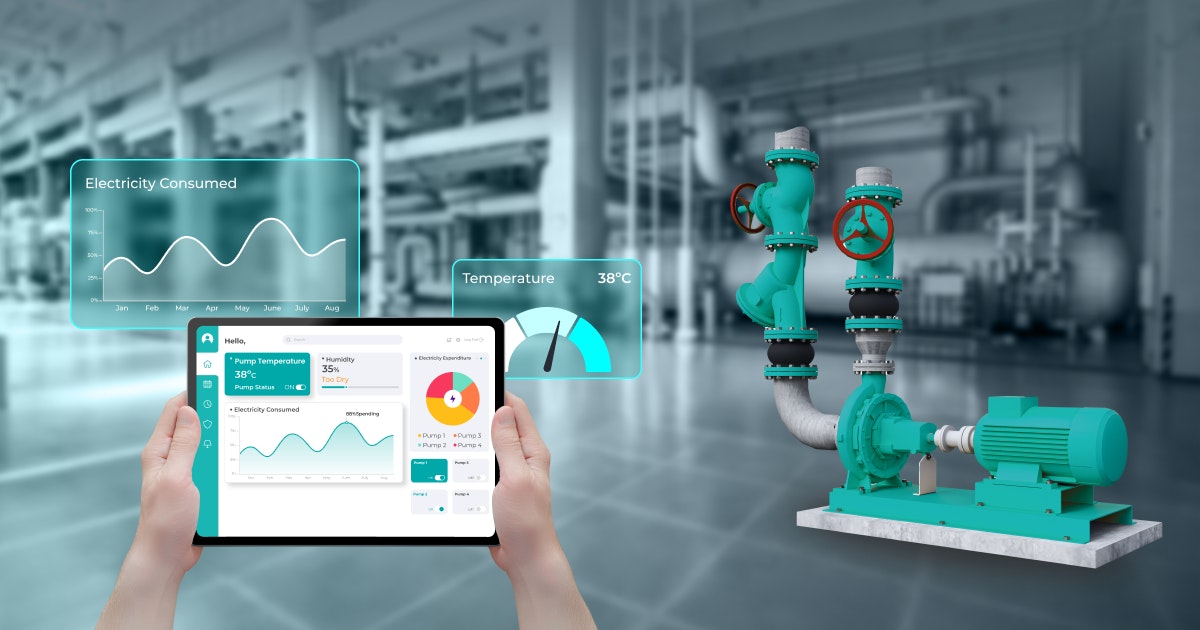

2. Real-time water quality monitoring

IoT sensors can monitor different parameters in water treatment in real-time and provide continuous data on parameters such as turbidity, pH, dissolved oxygen, total dissolved solids, and so, which can be used to optimize the treatment process and ensure compliance with regulatory standards.

For example, if the pH level of the water is too high or too low, it can corrode the treatment plant equipment or interfere with the chemical reactions occurring in the treatment process, causing reduced treatment efficiency and poor water quality.

An IoT solution for water treatment can continuously monitor the parameters and provide real-time alerts to the plant operators if they fall outside the desired range. This enables them to take immediate corrective action to prevent any damage to the equipment or negative impact on water quality.

3. Systemic energy efficiency

IoT solutions can help reduce energy consumption by optimizing energy-intensive equipment in water treatment plants. The sensors installed in the system collect data on the performance of the equipment, such as the energy consumption of the pumps, chillers, and heaters.

By analyzing this data, the IoT system can identify areas where energy consumption can be optimized, such as reducing the frequency of operation of energy-intensive equipment during off-peak hours or when water demand is low.

4. Remote troubleshooting

Plant operators can diagnose and resolve issues remotely, such as controlling temperature, pH, or dissolved oxygen (DO). This means that plant operators can access the IoT solution from a remote location, such as their office or home, and use the data collected by the sensors to monitor and control the treatment process.

For example, if the IoT solution detects the pH or DO levels below the desired range, the operator can remotely adjust the treatment process to correct the issue.

By enabling plant operators to diagnose and resolve issues remotely, the plant can avoid delays in waiting for an on-site technician to arrive. Additionally, remote troubleshooting can reduce maintenance costs by minimizing on-site visits and reducing the time required to resolve issues.

5. Predictive maintenance

This involves using sensor data to predict when equipment such as chillers, heaters, or other equipment may need maintenance or replacement. The IoT system continuously monitors the performance of the equipment. It collects temperature, pressure, and flow rate data to analyze and detect any anomalies or abnormalities that indicate potential equipment failure.

Based on this analysis, the system can generate alerts or notifications to plant operators, indicating the need for maintenance or replacement of equipment. For example, if the system detects that the flow rate through a particular pump has decreased or that the temperature of a chiller has increased, it can alert the plant operators that maintenance is required.

6. Water conservation

Water conservation is essential for water treatment, as the process can consume a significant amount of water. An IoT-based system can help reduce water wastage by adjusting the flow rate and the amount of water used.

This can be achieved by monitoring the water flow and usage data using sensors and analyzing this data to identify areas where water consumption can be reduced.

For example, the system can analyze data to determine the minimum flow rate required for a particular process or identify any system leaks that need to be addressed. By making these adjustments, the system can help minimize water wastage and reduce the overall water footprint of the treatment plant.

Let's Integrate IoT into Your Water Monitoring Systems!

Let's Get StartedOver to you

So you see, IoT-enabled water treatment plants can use various monitoring parameters to ensure optimal efficiency, reduce downtime, and enhance overall water quality. It is an essential step for manufacturers, plant operators, and engineers to take to create better products.

So, what are you waiting for? IntuThings IoT experts can help launch IoT-powered apps perfect for water treatment plants. Whatever your business requirements are, we can bring your IoT application development project to life.

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a customized roadmap and strategies to leverage IoT for smart liquid monitoring systems.